In 2009, Wynnewood resident Jacob Hurwitz took a trip to London with his wife and purchased something quintessentially London: a trench coat. Impressed with the coat’s quality, he looked into the British label, Aquascutum.

Founded in 1851, Aquascutum — name derived from the Latin for “water shield” — created the fabric for the coat Sir Edmund Hilary wore on his ascent of Everest. The coat was ideal for keeping out Britain’s wet weather, and it set Hurwitz to wondering: It rains in the U.S. too. Could he find a coat this nice that was made in America?

“I asked who makes this in the United States? And the answer was no one,” he says.

Today, Hurwitz is that someone. The co-owner of American Trench oversees a stylish, hard-wearing catalog of clothing and accessories made in factories throughout the U.S., furthering the growing movement away from fast fashion — and toward sustainability. In November, American Trench opened its first brick-and-mortar on Lancaster Avenue in Ardmore, the main street of the Main Line.

From sales associate to clothing exec

Hurwitz’s path to launching American Trench was circuitous. After graduating college in 2001 with a degree in math, he had an offer for a job in data analytics, but the offer got pulled when the U.S. briefly entered an economic recession after the 9/11 attacks. He didn’t know what to do, until a friend who worked at throwback sports apparel mecca Mitchell & Ness suggested he apply to work there.

For the next nine months, Hurwitz worked on the M & N sales floor (it was a busy time, as Reuben “Big Rube” Harley was taking the throwback sports apparel global). Hurwitz even helped with replica jersey research. Then, he left to attend the University of Pennsylvania’s master program in education, taught high school math for five years, and joined Exelon as a risk and business analyst. Outside of the stint at Mitchell & Ness, he didn’t think he’d work in apparel long-term.

“We have products that work that people love and come back to us for, year after year.” — Jacob Hurwitz

“I finished that and I was like, Oh, well, that was interesting. That’ll never happen again,” Hurwitz says. “Now here I am with a company in the clothing and apparel space. You never know when those old jobs are going to end up affecting your later career.”

While at Exelon, he started pondering his own company. His London purchase — and subsequent quest to find something similar made in the U.S.A. — presented an opportunity.

He called long-time family friend David Neill, then going to graduate school for design, to see if he knew of any U.S. brands that were equivalent to the UK’s Aquascutum. Neill didn’t know of any either. “There was no one,” Hurwitz reiterates. His friend was game to help him fill that niche.

In 2013, Neill and Hurwitz launched a Kickstarter campaign that raised $19,108 for them to start an American trench business. Their deal: Neill would design the clothes (and continue to work for his family’s painting business), and Hurwitz would manage business operations day-to-day.

They took those funds, combined them with some of their own money, and started looking for manufacturers to partner with.

Finding American makers

That task was easier said than done. One just has to take a walk through Kensington and count shuttered button factories and hosiery mills to know that much of American textile production has been shut down over the last several decades. In 1990, 1.6 million people worked in apparel and textile production factories in the U.S. Today, only 410,000 Americans work in these industries, Reuters reports.

Zooming out even further: In 1960, the average American household spent 10 percent of its income on clothing and shoes, fewer than 25 garments and pairs of shoes per person annually — 95 percent of which were made in the U.S. Today, we spend much less (closer to 4 percent of our income) on apparel, and buy much more of it — by a 2013 estimate, 70 garments per year. In other words, clothing has become much cheaper. And only 2 percent of what we buy is made in the U.S.

Hurwitz spent hours searching the internet looking for U.S. makers of ready-to-wear items. There’s still no collected resource for finding these companies, he says. He had to follow up on “any tiny little piece of information.”

But he persisted, finding a factory in New Jersey to make trench coats. In 2014, with help from an angel investor’s line of credit, he began to sell them online.

In his search for U.S. manufacturers, he found more than coat makers, however: A sock mill in North Carolina. A sweater weaver in Brooklyn. A down coat sewer from New Jersey. Beanies from Texas. He realized American Trench could and should be much more than coats.

Today, his company collaborates with more than 25 manufacturers across the country to make all of the above, plus shirts, pants, shoes, other outwear — even underwear — for them. Some of these items bear their labels from their manufacturers; some are branded American Trench; all have detailed information about where and how they’re made. An updated version of the trench, now made in Boston, will debut next year. (They’re currently sold out of trenches.)

Hurwitz estimates that 30 percent of the textiles and more than 40 percent of the yarns in the apparel they carry are made in the U.S. He says last year, they spent well over $1 million on inventory from American manufacturers.

Why American-made matters

It’s not just that Hurwitz believes American-made clothes are well made. He also wants to create stable, family-supporting jobs for people who, like his parents, worked as professionals – his dad was an electrician; his mom, a nurse — without having to go to four-year colleges. As a teacher, he felt like he had to push kids to go to college, even though he knew that wasn’t the only way a person could have a successful career.

“In the history of this country, we created all of our wealth by taking raw materials and turning them into manufactured goods, and in about the past 20 to 30 years, we abandoned that as being a path to success, which has been well documented as being foolish,” he says.

“We’re not going back to 1950, but it was a mistake to abandon manufacturing. I felt like if I wanted to be a part of a solution and a future that I felt like was the right way forward that [American manufacturers] needed to be a central part of the brand ethos.”

Lynda Kelleher is one of the manufacturers Hurwitz works with. Her company, the Massachusetts-based Classic Apparel Designs Inc, makes topcoats, overshirts and is currently producing a new trench coat for the brand.

“I’m committed to being in the United States, and we’ve seen over the years, a trend of people who do try to buy a good portion of goods that were made here.” — Lynda Kelleher, Massachusetts-based Classic Apparel Designs Inc.

Kelleher has worked in textile and apparel factories since the 1970s. Before launching her own business, she did bookkeeping for other factories. She remembers watching one facility she worked at gradually layoff workers, whittling down its staff from 200, to closing its doors. She likes working with American Trench because Hurwitz is committed to working with businesses like hers.

“A lot of companies look at the bottom line and see that they can get things cheap, so they just continually buy from overseas. It’s not really helping our economy,” she says. “I’m committed to being in the United States, and we’ve seen over the years, a trend of people who do try to buy a good portion of goods that were made here.”

Making clothes in America is better for the environment as well. Over the last several years, a hundreds of companies have launched with slow-fashion agendas, an attempt to reduce the environmental damage caused by the industry — the world’s the third highest polluter. B corp Happy Earth, for example, makes clothing from organic materials and donates to nonprofits that help plant trees and clean up trash. Philly-based Grant Blvd (also a B corp) makes clothes from dead stock and recycled fabrics.

For Hurwitz, working with American manufacturers is one of the most sustainable things his company can do. U.S. environmental laws limit factories from polluting with chemicals from manufacturing.

He’s intentional about choosing clothing that will last, too — not just to wear once and get rid of because it ripped, or because it went out of style.

Kelleher says she and Hurwitz talk constantly during the design and manufacturing process to ensure the product meets American Trench’s standards and to use her expertise to make improvements He’s visited her — and visits every factory they work with — to ensure safe working conditions.

An American Trench storefront

In the Ardmore store, retro cotton gym socks ($14) woven in Hickory, NC line a corkboard on the wall. Classic navy wool peacoats ($495) and soft plaid flannel button-downs ($195), both cut and sewn in Boston ($495), hang from racks. A ladder shelf holds folded Shaker-knit turtle sweaters knitted in upstate New York ($150) and button-fly jeans sewn from Japanese denim ($275), in Virginia.

A shelf of shoes include thick-soled suede moccasins ($375) from Maine. They even have boxer-briefs ($45/pair) made to military-level specifications in Los Angeles — and cords, with pleats ($250), from, of course, Brooklyn. Most of the items are men’s, or unisex, but dedicated women’s pieces include luscious, merino wool shawls ($255) and joggers ($225), also knit in Brooklyn.

American Trench clothes have a preppy meets outwear vibe, Vintage L.L. Bean or Eddie Bauer or really-back-in-the-day Banana Republic, with a side of luxe athleisure.

Hurwitz believes opening a physical retail location will give customers a chance to experience the clothes IRL — not just for fit or color, but also for tangible quality. Hurwitz has trained staff to talk with customers about the brand’s mission and story.

“It was very exciting to be able to showcase all of our products physically for the first time ever and see them all together, not in boxes, and to see people try stuff on and interact with it,” Hurwitz says. “It is really amazing to be able to connect with people on the ground floor.”

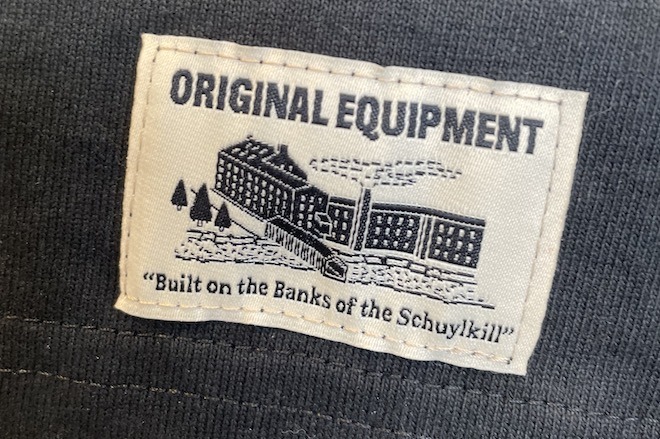

They need the space, too. The brand has had a 26 percent annualized growth rate since 2015. In April of 2022, they launched the subbrand Original Equipment, a street- and workwear-inspired look, with pricing between $75 for a t-shirt to nearly $300 for a chore coat — displayed alongside the rest of the line.

Before the Ardmore shop, Hurwitz and his team of 13 employees packed and shipped all of the company’s orders in an old fulfillment center that didn’t have enough space to keep up with demand. Hurwitz needed to find a warehouse — or a retail store where he could both sell clothes and house shipping operations. He found it between a nail salon and an optical store in Ardmore.

American Trench’s flagship held its grand opening on November 25 — aptly, Small Business Saturday. They’re already seeing a decent amount of foot traffic on Lancaster Avenue (launching during the busiest shopping season didn’t hurt); this year, the company is on track to hit $3 million in revenue from online and retail operations.

Hurwitz is surprised by how many people stop in, unaware that they’re a local company — and excited for more people to hear the brand’s story.

“We have products that work that people love and come back to us for, year after year,” Hurwitz says. “But there are so many people whose digital footprint never crosses ours. They don’t know we’ve been in business for a decade in Ardmore.”

American Trench, 15 E. Lancaster Avenue, Ardmore. Open Tuesday–Saturday, from 11am to 7pm, and Sunday, from 10am to 3pm.

![]() MORE BUSINESS FOR GOOD FROM THE CITIZEN

MORE BUSINESS FOR GOOD FROM THE CITIZEN